About Us

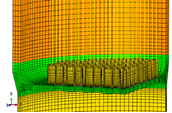

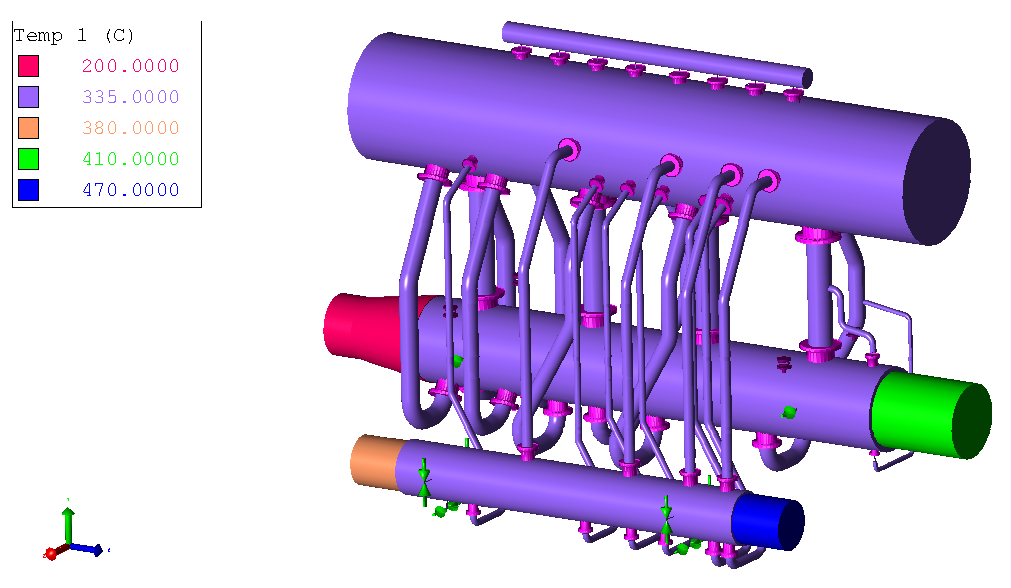

Verification of fixed tubesheets with Limit-Load Analysis for the verification of global stability, Elastic Analysis for the verification of resistance against local mechanisms and Ratcheting Assessment according to Part 5 of ASME VIII Div.2 for the Tertiary Quench Exchangers (TQE ) - INEOS Olefins & Polymers USA (Chocolate Bayou, TX) |

|

Finite Elements Analisys of the Closure Thread of the tank and of the internal tube side components (TEMA Type DEU Screwed Closure - Horizontal Type) according to ASME VIII Div.2 Edition 2015. Assial-symmetric analysis of the complete model and Solid 3D Analysis of detail for the verification of the Z-Forged and the buckling verification of the Partition Box - ENI Refinery SANNAZZARO DE BURGONDI |

|

Verification and Design with finite element analysis of the Sweepolets 20 "× 36" welded on a cone, Static Verification according to ASME VIII Div.2 Part 5 and Testing of Creep-Fatigue according to ASME III Section NH - SHELL PUGET SOUND |

|

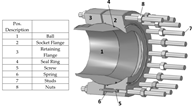

Design, Verification and Technical Support for the Qualification Test of the Misaligment Flange , in particular preliminary study of different seal ring geometries and design of the Misalignment Flange geometry - CABINDA GULF OIL COMPANY LTD |

|

Calculation and Experimental Verification with Laboratory Test at the University of Bergamo of the SIF of the Reduced TEE SMLS 6 "× 4" - NUOVO PIGNONE (GE Oil & Gas) |

|

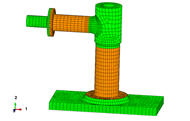

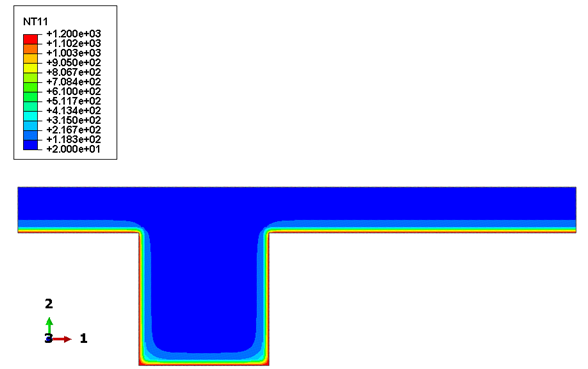

Design and verification with the Finite Elements of the Cone-Tee Junction subject to the different Thermal Expansion due to the refractor inside the cone - SAFCO III AMMONIA PLANT RIP PRIMARY REFORMER |

|

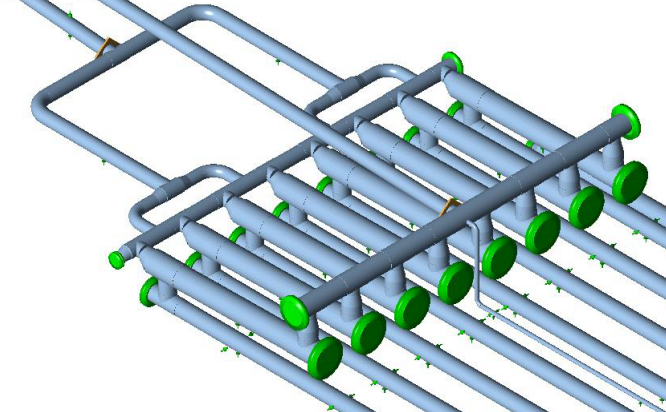

Piping Stress Analysis of the Finger Type Slug Chather according to ASME B31.3, performing the Static Verification for the thermal and occasional conditions, the Fatigue Assessement in the Operating conditions and the Verification of the Natural Frequencies - KHAZZAN CENTRAL PROCESSING FACILITY (CPF)

|

|

Piping Stress Analysis of the New High Pressure Carbamate Condenser according to ASME B31.3 considering the thermal and occasional wind and earthquake conditions - LORDEGAN AMMONIA AND UREA PROJECT |

|

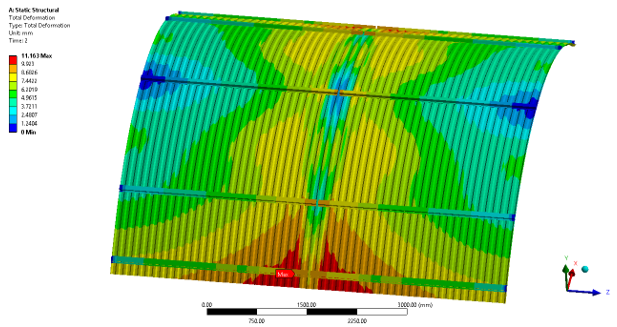

Static verification of the Fire Resistance of the corrugated sheet covering the TUNNEL DU CHAT (FR)

|

|

Thermal Analysis for the Calculation of the Minimum Thickness of the Fire Protection System of the standard sections performed according to the "fire curve" UNI11076/2003 (DM "Safety in railway tunnels" of 28 October 2005) for the Milan-Naples railway line (urban line high speed) BOLOGNA (CAMERONE SALESIANI)

|